Motor parts cutting/polishing products

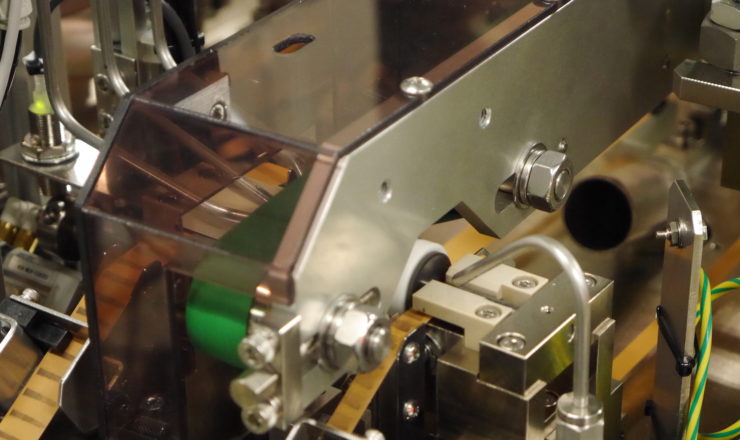

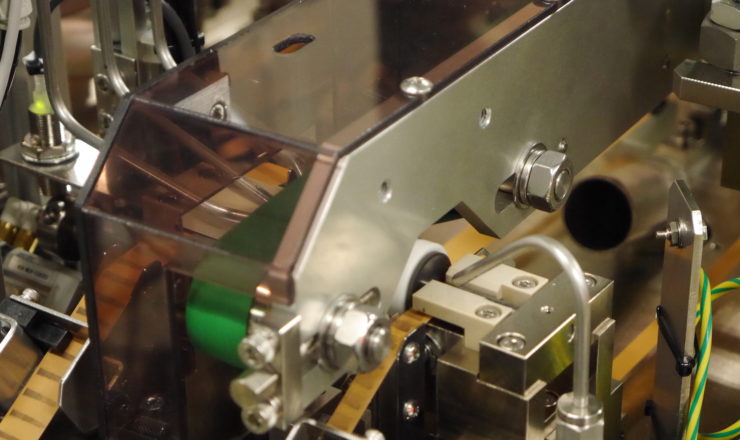

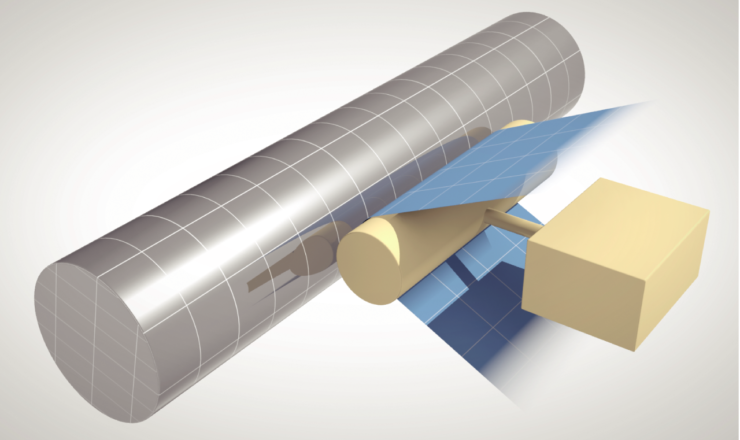

High precision commutator cutting, rotor outer diameter cutting, and film polishing of both axes are realized with the V-block receiver and belt drive.

Our lapping film polishing machines have wide processability

and can achieve a surface accuracy ranging from nanometers to micrometers.

Since a high level of proficiency is not required,

considerable time can be saved, and the polishing process can be automated.

In addition, since film polishing is fixed-abrasive processing, there is little, if any, dust generated in the environment. Clean processing, therefore, can be achieved.

Advantages of film polishing

Film polishing is a clean advanced technology that produces almost no dust and meets the needs of society.

Industries where lapping film polishing play an active role

The main lapping film processing equipment types developed by Sanshin include flat lapping machines, internal diameter lapping machines, and shaft external diameter lapping machines. These devices are utilized in industries, such as the automotive and electronics industries.

Lapping Film

In the lapping film polishing process, the film is fed in sequence at a low speed, and the work is always polished with a new abrasive surface of the film, which makes the finished surface roughness uniform and provides consistent machining efficiency and quality.

Sanshin Co., Ltd. is committed to being a customer-centric and creative engineering group.

We wish to be a company that is sensitive to needs of the times, that is, always keeping a challenger’s spirit in our minds, that takes on the challenge of “Monozukuri (Manufacturing)” while keeping our eyes on the world and that can contribute to our society.

When we talk about manufacturing in the city of Nagaoka, one of the key points is the manufacturing of devices and machines. The personnel at Sanshin believe that the basics of manufacturing lie in addressing the needs of the changing times and fully utilizing our own precision machining technologies to fulfill customer requirements that are becoming ever more diversified and sophisticated.

Our basic philosophy is to commit ourselves to being a customer-centric, creative engineering group and being a company that is sensitive to the needs of the times that always has a challenger’s spirit in mind and that takes on the challenge of “Manufacturing” while keeping our eyes on the world. We aim at being a company that can contribute to society.

We started our business in October 1957, naming the organization as Sanshin Tokki Manufacturing Co., Ltd. For more than half a century since then, we have been managing this organization as one that can respond to the needs of the times.

To make lapping film usable on a variety of materials, a wide range of film types have been prepared, from which it is possible to select the proper type of film that meets the required finishing surface roughness.

In addition, the stable quality of your products is assured when you install our film polishing machine in your system.

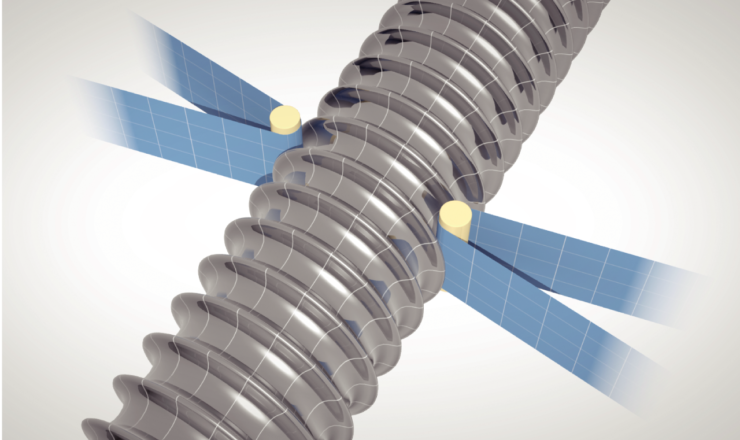

High precision commutator cutting, rotor outer diameter cutting, and film polishing of both axes are realized with the V-block receiver and belt drive.

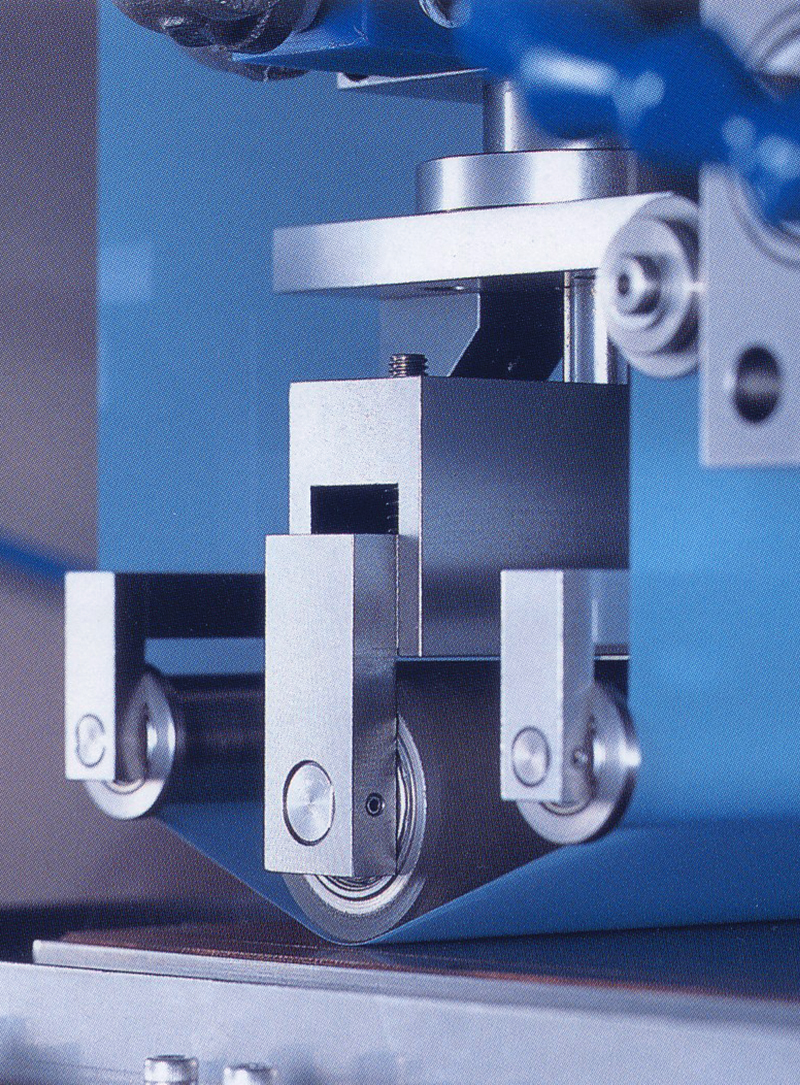

By changing the film width and film application method, it is possible to polish the outer diameter part of all kinds and shapes.

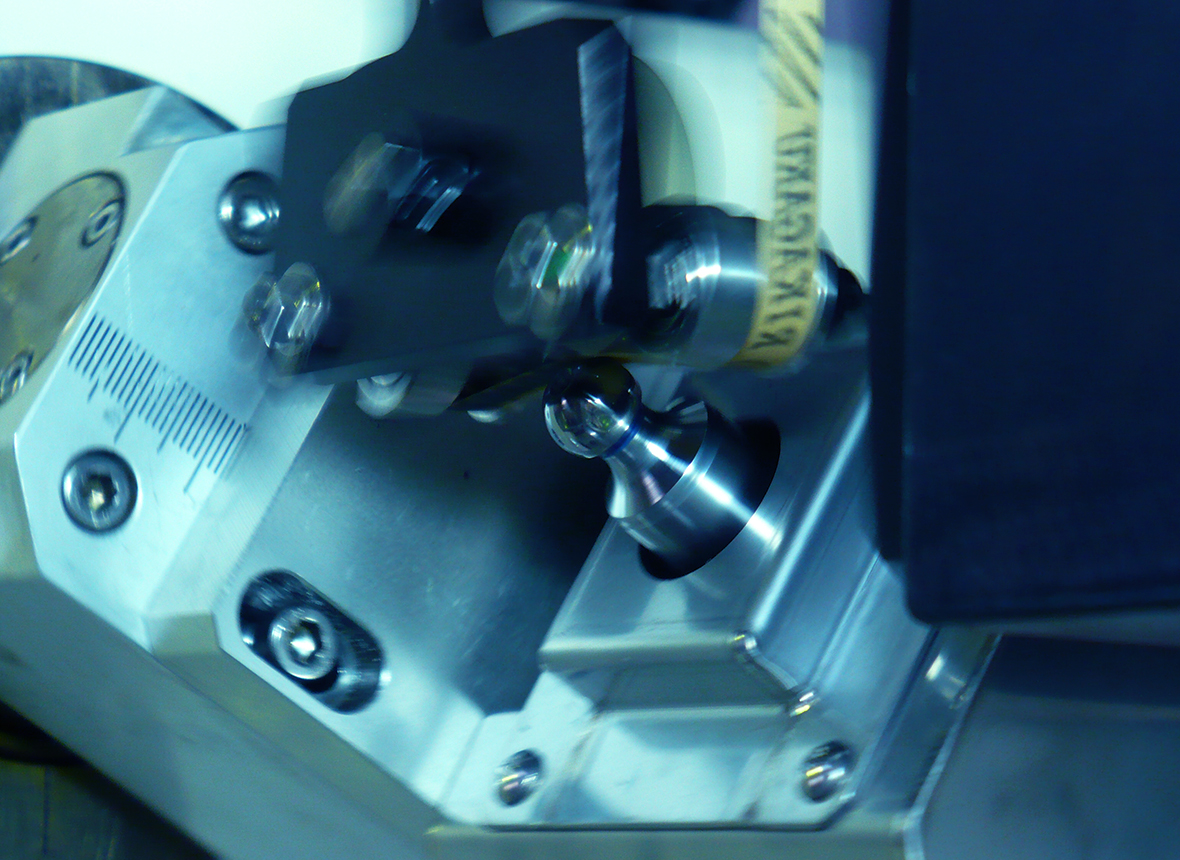

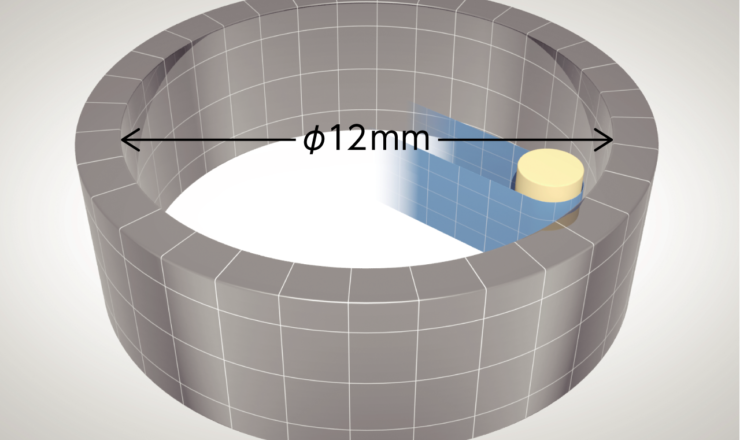

Our innovative method to reel in film also allows to perfectly polishing of the inner diameter.

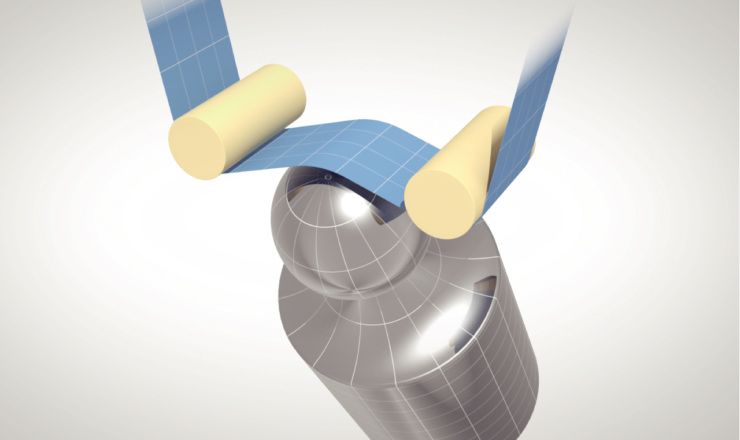

By continuously rotating the item to be polished, spherical surfaces can be polished to perfection as well.

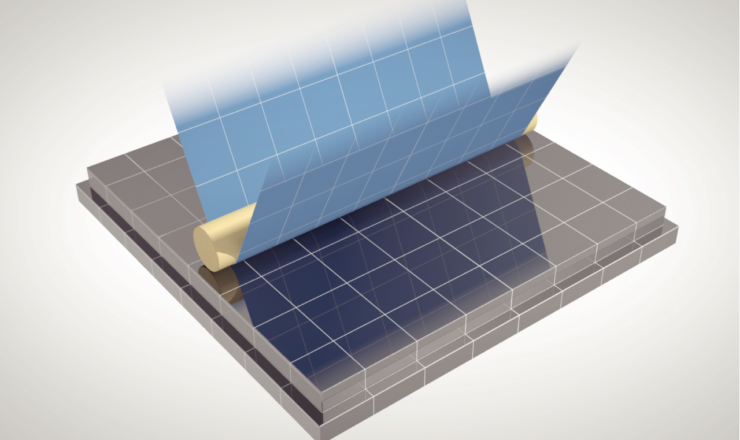

Our polishing machine allows our customers to precisely determine the level of polishing and also ensures that flat surfaces are leveled perfectly with no unevenness or protrusions.

Conventionally, ball screws were processed by grindstone polishing or the final process was hand-finished.