Outer Diameter

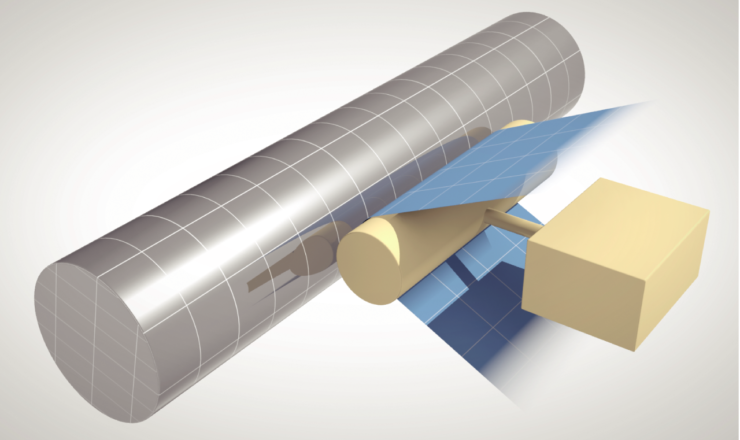

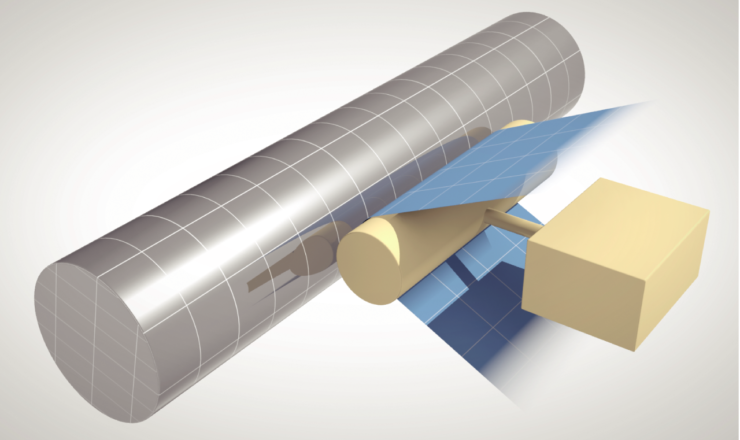

By changing the film width and film application method, it is possible to polish the outer diameter part of all kinds and shapes.

To make the lapping film usable on a variety of materials, a wide range of film types have been prepared,

and it is possible to select the proper type of film that achieves the required finishing surface roughness.

In addition, the stable quality of your products is assured when you install our film polishing machine in your system.

By changing the film width and film application method, it is possible to polish the outer diameter part of all kinds and shapes.

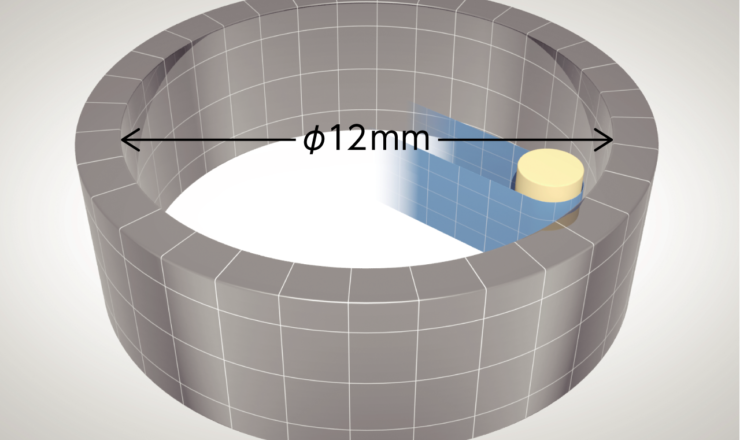

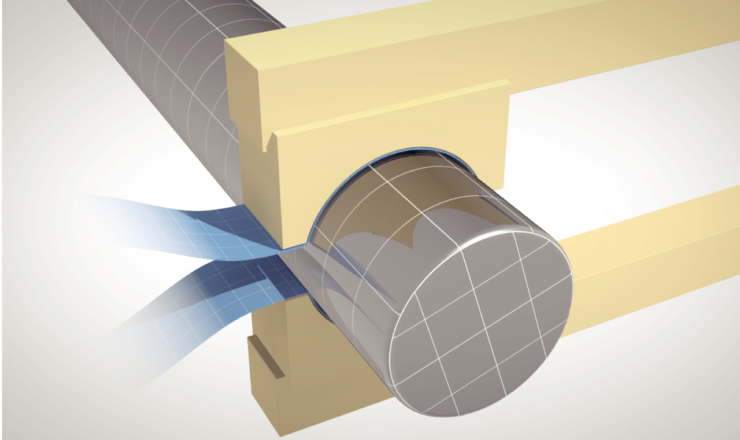

Our innovative method to reel in film also allows to perfectly polishing of the inner diameter.

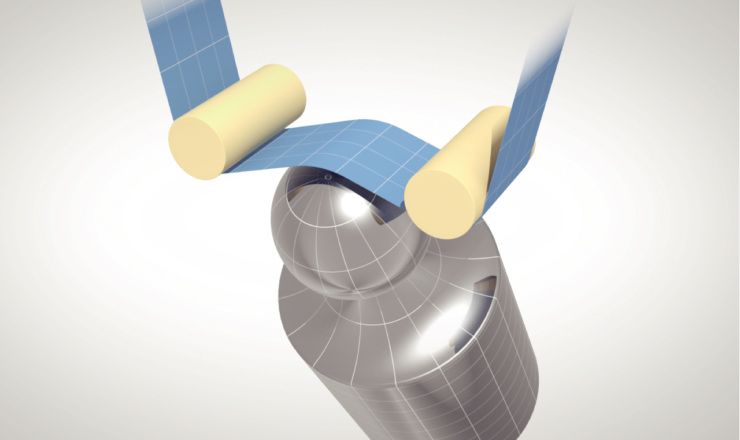

By continuously rotating the item to be polished, spherical surfaces can be polished to perfection as well.

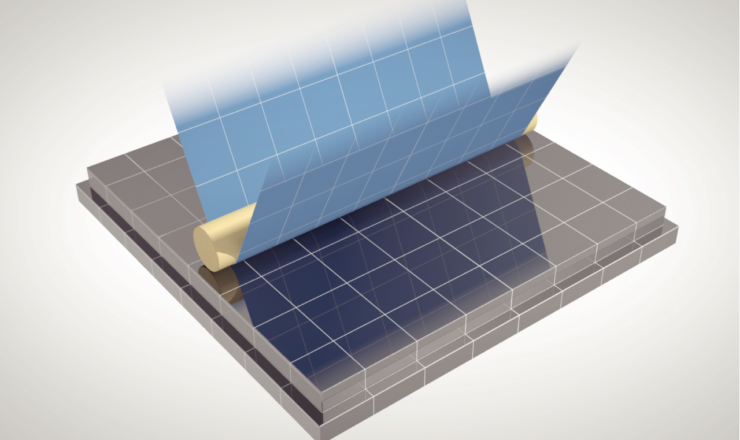

Our polishing machine allows our customers to precisely determine the level of polishing and also ensures that flat surfaces are leveled perfectly with no unevenness or protrusions.

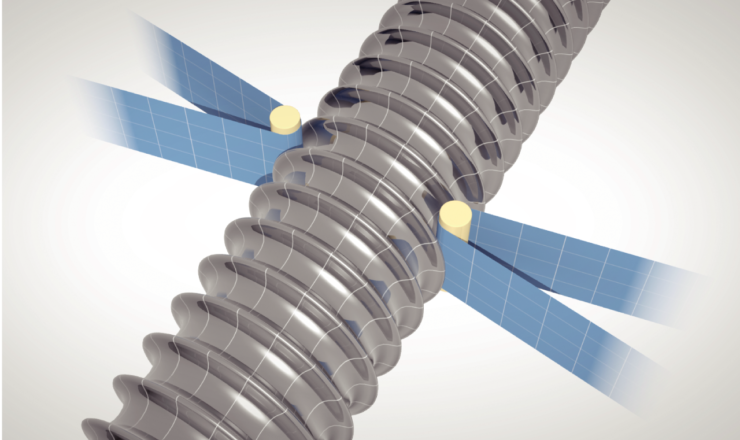

Conventionally, ball screws were processed by grindstone polishing or the final process was hand-finished.

We are also proud that our film polishing machine can be used to provide precision finishing of the protruding surfaces on crankshafts and camshafts, so they will run perfectly smoothly in high-performance engines.

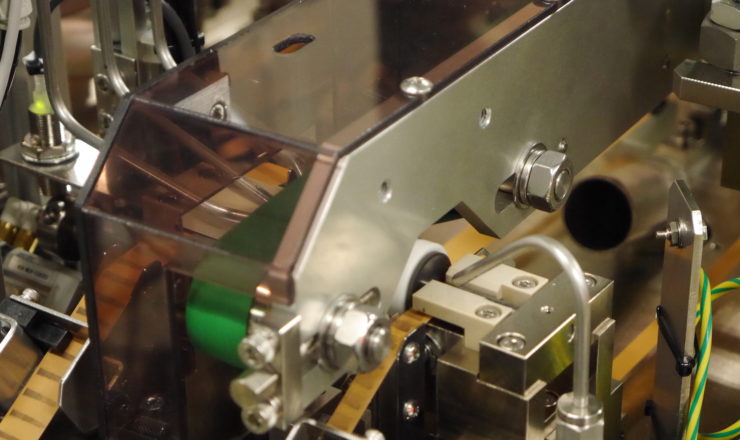

High precision commutator cutting, rotor outer diameter cutting, and film polishing of both axes are realized with the V-block receiver and belt drive.