Technologies

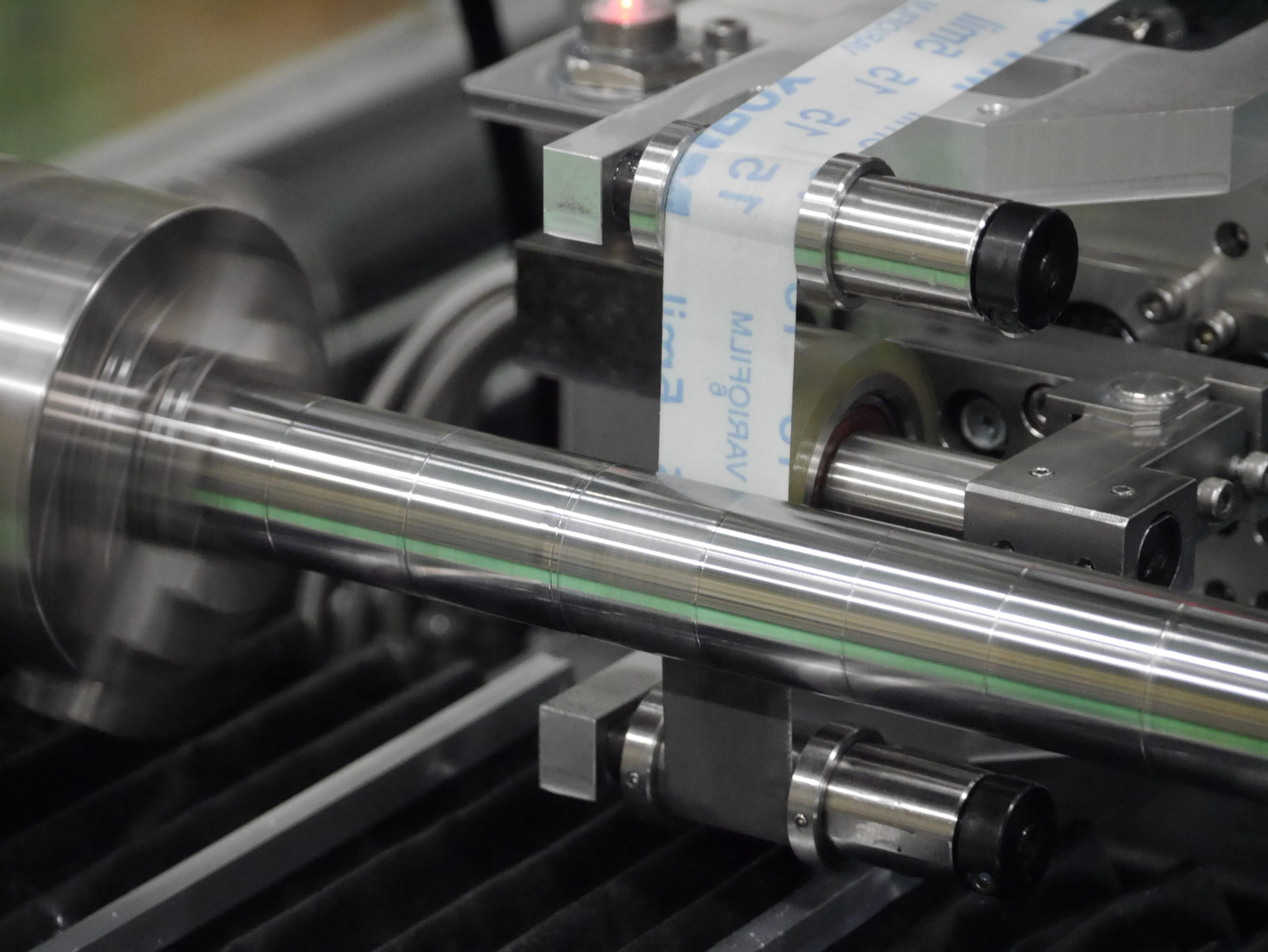

About lapping film polishing

Film polishing is a clean advanced technology that produces almost no dust and meets the needs of society.

Advantages of film polishing

Infinite possibilities that extend from nanometer to micrometer

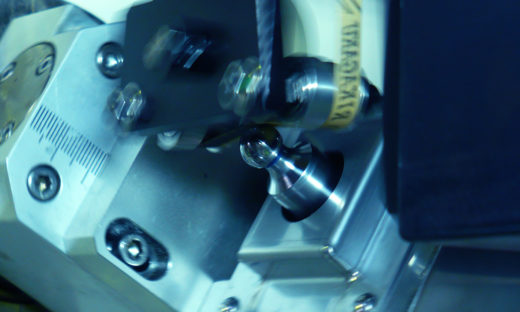

The film has various types of abrasive grains, such as aluminum oxide, silicon carbide, and diamond, which make it correspondent to a wide variety of materials. Furthermore, it is possible to finish the surface to a suitable roughness by selecting particle sizes from 100 to 0.1 micrometers.

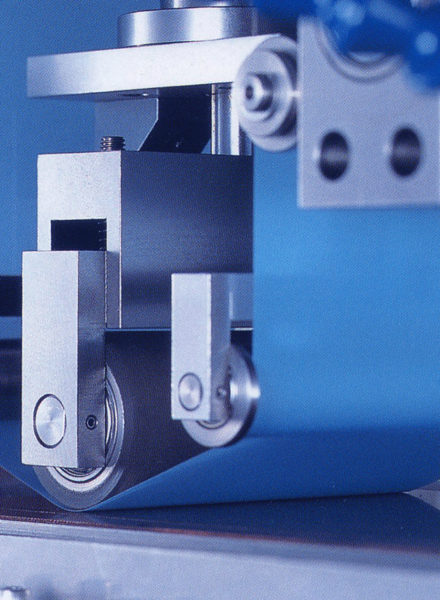

By incorporating this into the equipment, the technology to conduct a uniform finish without variations in surface roughness is Sanshin’s proprietary technological method.

Working hours and labor cost efficiency

Super-finish processing requires a high degree of skill; however, due to its special design, our film polishing machine is easy to operate and does not require a high degree of skill. Work time is greatly shortened and automation becomes possible. In addition, compared to other methods, such as grinding stones and buffs, since we always feed the film constantly at regular intervals and process with a new grinding surface of the film, quality control and uniform finishing can be easily performed without dressing the grinding surface of the grinding wheel.

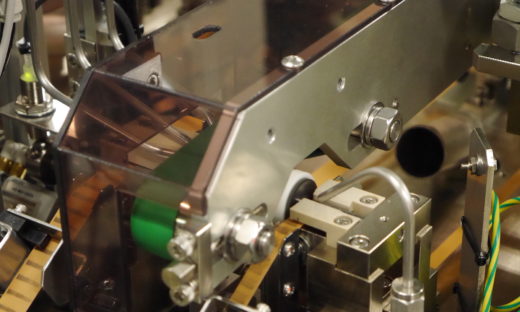

Environmental conservation–Clean technology. Advanced technology suitable to society

While environmental conservation and clean technology have become social themes in recent years, since film polishing involves fixed-abrasive grains, clean processing can be realized in terms of environmental aspects as little or no dust is raised. It can also be used in both dry and wet conditions.

Outline of Lapping Film Polishing System

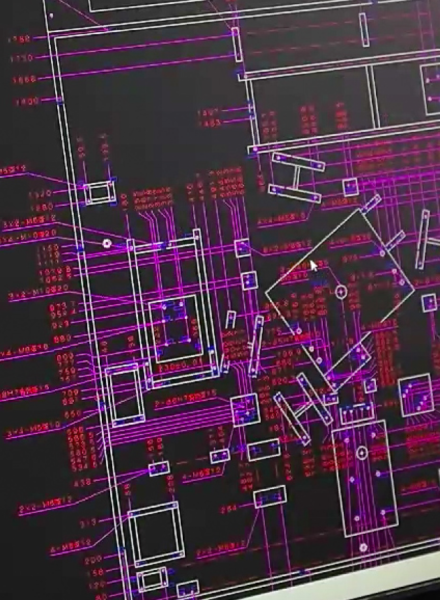

The technology level of the latest high-tech products, including those in the automotive industry, construction machines, and other industrial machines, has been improved to a substantial degree, and the marketing of our tape polishing systems is now indispensable for various parts.

Furthermore, the underlying concept in the grinding technology is the improvement in fuel costs and the reduction of CO2, and actions, such as reviewing the machining processes for environmental friendliness and improving machining efficiency, are now attracting immediate attention.

In addition, in the electronics industry, it is popular for the grinding work in the machining process of the final finish to use loose grains for lapping or polishing. In recent years, however, a grinding method using lapping film (fixed grain) has been employed frequently in the final grinding process of high-tech products, including information and communication equipment, and this method is gaining popularity as a grinding method that results in a cleaner working environment.

In recent years in particular, this method has been highlighted in various industries throughout the world in light of clean technologies for preserving the environment. We are continuing with the research and development of tape polishing systems endlessly to achieve further system precision and efficiency.

Fortunately, Japan has a lead over other countries in the field of lapping film, and we will continue the development of lapping films and systems that match the future social climate, aiming to be the leading company in the world in the future.

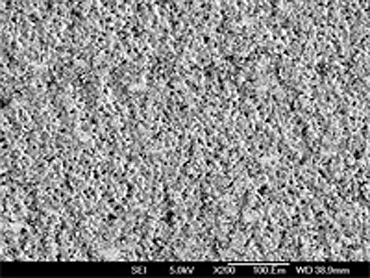

Lapping Film Surface

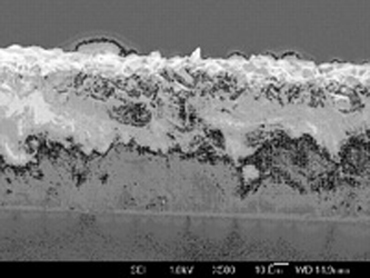

Lapping Film Section