TECHNOLOGY

About lapping film

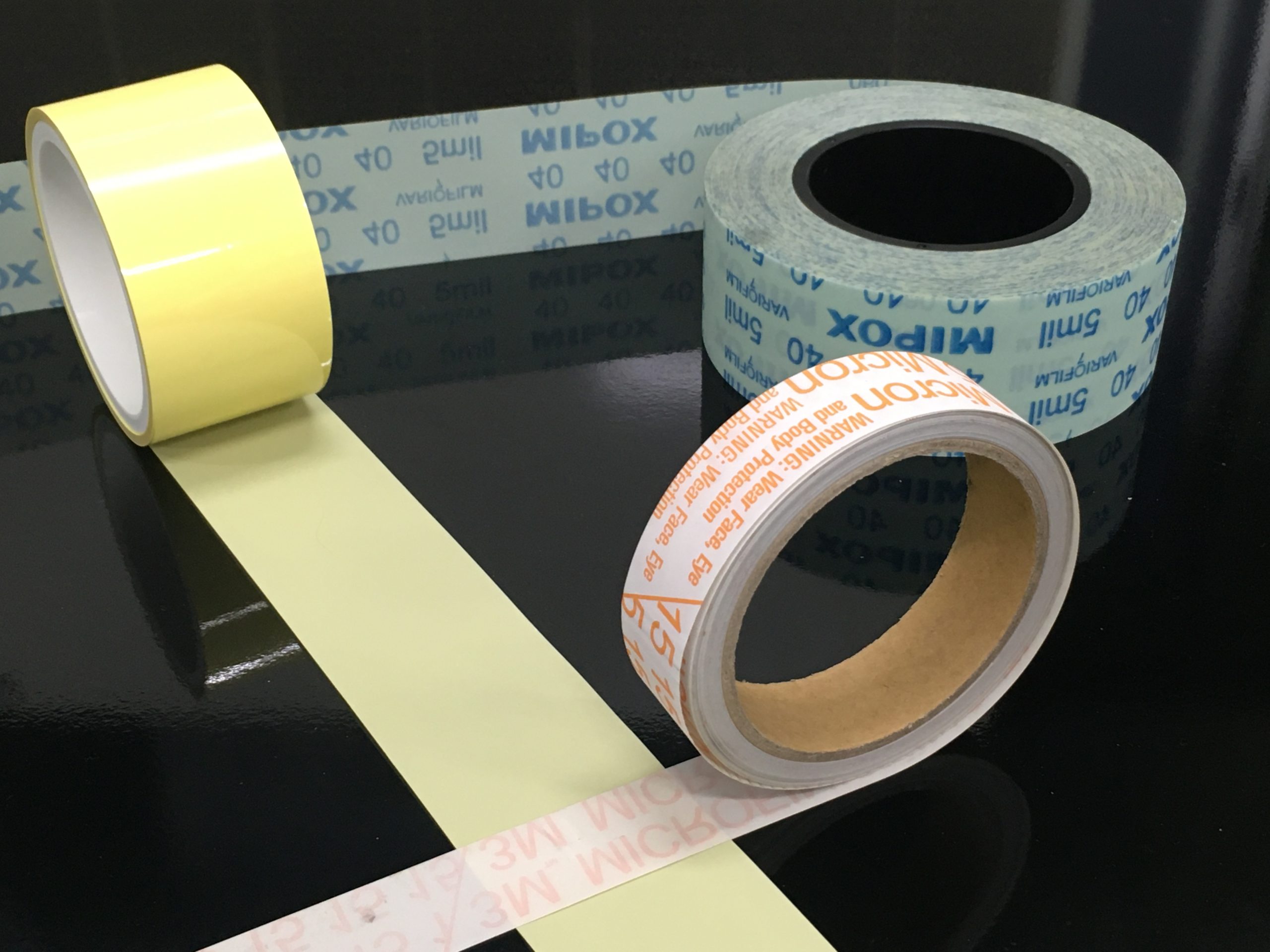

Lapping Film

Presently called the high-technology age, efforts aimed at making machining and finishing work finer are increasingly expanding.

As a manufacturer specializing in film polishing systems, we have been working together with film manufacturers to research, develop, and market polishing sheets and papers. In addition to conventional abrasive sheets and papers (for the electrostatic coating method), fine polishing materials (for the roller coating method) have become available and exhibit tremendous power in surface polishing processes, enabling highly accurate and precise finishing. We will continue to develop advanced surface finishing systems under our motto: “From rough grinding to super fine finishing.”

The following effects can be expected when using a lapping film.

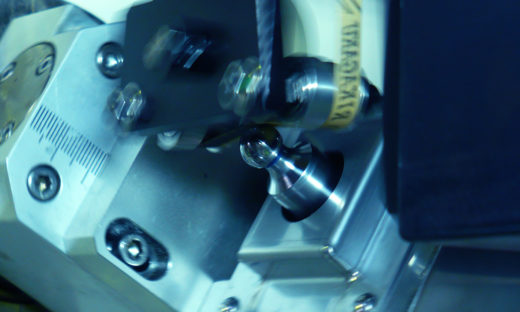

High-accuracy and ultra-precision finishing

Since micro abrasive grains are dispersed and applied evenly on the film using a special binder resin, no deep scratches are generated and uneven grinding can be prevented. The result is high-accuracy flatness and super-finishing quality.

Water resistance and oil resistance

The use of a polyester film for the base provides water and oil resistance and makes wet-type grinding possible. (Do not use aromatic solvents such as thinners.)

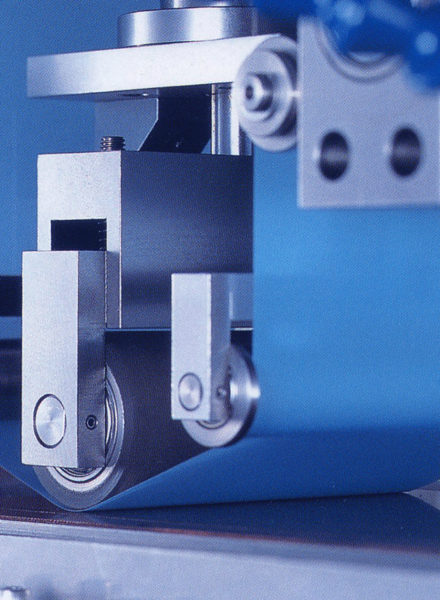

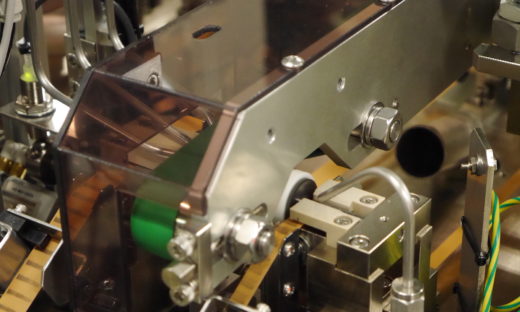

Automatic grinding and quality control

The polyester film used for the base is durable against tensile strength, tearing, etc., which enables automatic grinding with machines, as well as mass-production, thus, making quality control easier.

Advantages of Lapping Film Polishing

- Super-precision finishing is possible, down to 0.01 μm.

- Controlling roughness is easy. The lapping film types are abundant.

- Abrasive grains that ensure a uniform finish.

- Lapping finishes according to applications are possible by selecting abrasive grain materials.

- Fine deburring can be performed along with processing of surface roughness.

- The method can be applied for both dry and wet types. Although the dry type is employed in general, powder dust is seldom generated.

- The processing environment is clean and compact. In addition, handling can be done speedily. Furthermore, in case the dry type can be used, the method contributes to labor saving in the cleaning process.

- Although super-finish processing requires a certain level of skill, inexperienced individuals can perform the work.

- There is no burden of grinding compensation to deal with in terms of wear on the grinding stone and replacing the lapping film is simple.

Types of Lapping Film

| Abrasive grain: | WA = White alumina |

|---|---|

| Grain size | 0.1μm 〜 100μm |

Other special tapes on which the abrasive grains are coated in a different method are also available. Contact us for details.

Distribution of Lapping Film

We do not manufacture any lapping film products. However, we offer better quality lapping film through cooperation with various manufacturers.

We are ready to present estimates upon request.

Sanshin is an exclusive distributor or an agent of four manufacturing companies in Japan.