TECHNOLOGY

Comparison of lapping film polishing and various other polishing

Corporate Info

Comparison of lapping film polishing and various other polishing

Grinding is work conducted to finish surface areas. Basically, the method is applied to the work to finely grind or polish the surface area to make it smooth using a solid substance with higher hardness than the surface of the work piece. The surface treatment grinding is roughly classified as follows:

A method for grinding materials by attaching grinding material to the periphery (surface) of the grinding wheel (buff), which is made of cloth or other material, and rotating the buff on the material.

A method of grinding the work piece with friction that is generated by pressing the work piece on a belt rotating at a high speed.

A method of fine polishing by pressing the lapping film onto the work piece. The polyester film is thin, and the abrasive grains are evenly dispersed on the film, which ensures small fluctuations in the height of the major cutting edge, resulting in a good finished surface.

This method is frequently adopted for the final finishing of electronic parts. This is a grinding method using loose grains.

What makes this different from other grinding methods such as buffing?

Buffing and belt grinding generate powder dust, and they are not suitable for use in a clean environment.

Lapping film polishing offers excellent abradability, higher surface precision, and stability. Furthermore, barely any powder dust is generated; it is, therefore, excellent in terms of environmental aspects.

Buffing and belt grinding are manual processes and are heavily dependent on craftsmanship and experienced workers. In addition, the appropriate system offers low stability for any profile irregularity.

Lapping film polishing ensures an automated operation, thus, offering higher efficiency and stable profile irregularities.

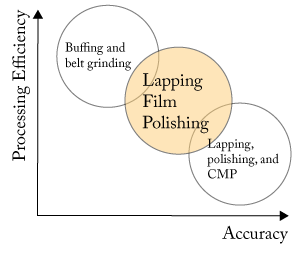

The processing efficiency of buffing and belt polishing is shown in the figure.